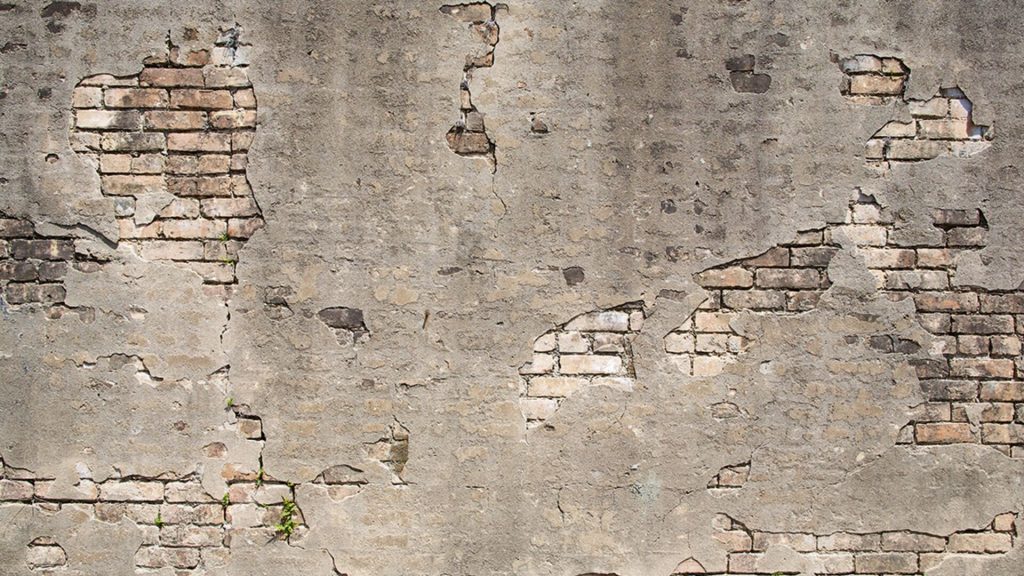

Ever wonder why there are so many ancient Roman structures still standing today? The Romans were expert builders and architects who constructed impressive temples, bridges, aqueducts, roads, and reservoirs, many of which are still in use centuries later.

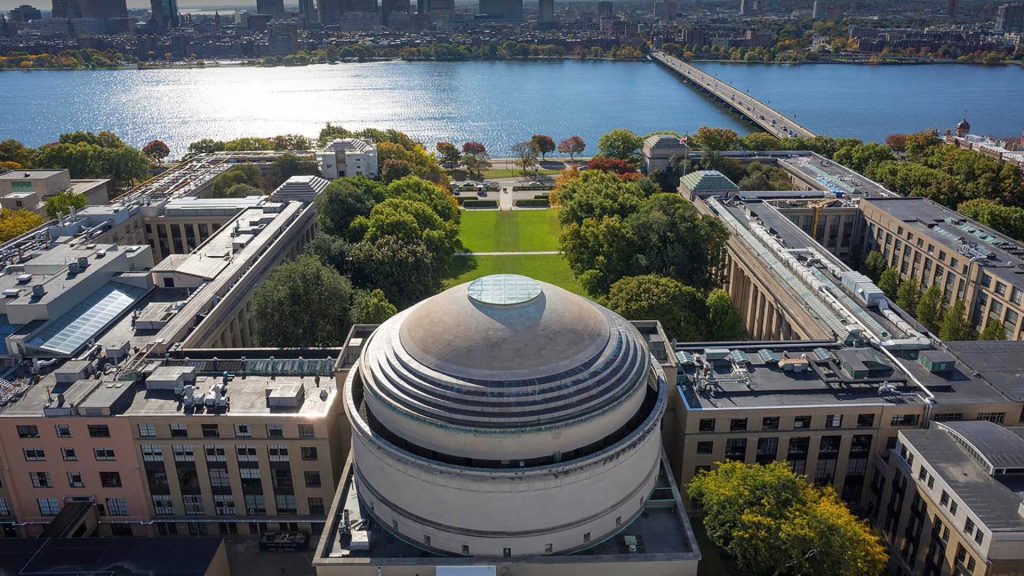

One of the reasons why ancient Roman structures have stood the test of time is the special type of concrete that was used at the time. Take a look at our roads and sidewalks today and you’ll see cracks, crumbles, and potholes appear after just a few years. So, what is the secret that made Roman concrete so durable? A team of scientists from MIT think they have the answer.

Incredible Strength and Incredible Longevity

Roman concrete gave incredible strength and longevity to the construction projects of the Roman Empire. The fact that so many of these ancient structures have remained largely intact is a testament to both the engineering skills of the ancient Romans and their choice of building material.

One prime example of this is the Pantheon. One of the best-preserved buildings from ancient Rome, the Pantheon is the world record holder for the structure with the largest dome of unreinforced concrete. When you remember that this building is two centuries old, that feat is even more amazing.

Pozzolana Concrete

We have known for a long time that the Romans added pozzolana to their concrete recipe. Pozzolana is a type of volcanic ash that takes its name from the city of Pozzuoli, Italy. Here, the Romans discovered a large deposit of the volcanic ash which they collected for their building projects.

There are numerous benefits to adding pozzolana to concrete mixtures. This material, for example, gives the concrete workability even when less water is used. With a lower moisture count, the concrete sets quicker. In addition, the pozzolana acts as a buffer to protect the concrete from potentially damaging sulfates and salt. Lastly, the pozzolana leaches out calcium hydroxide.

Lime, Another Key Ingredient

Lime is another key component to Roman concrete. A product produced from limestone, lime is basically calcium hydroxide. It has multiple uses and one of them is as an ingredient in concrete. Lime enhances the strength and workability of concrete.

Lime reacts with the pozzolana material to form a tightly bonded compound that increases the durability of the concrete. Scientists determined that Roman concrete contained both pozzolana and lime long ago, but that didn’t completely explain why Roman concrete was so superior, a the MIT team of researchers found out.

Still Not Quite Right

Even though we know that the ancient Romans used pozzolana and lime in their concrete mixture, efforts to recreate it resulted in a product that was close, but still not quite right. That’s why a group from the Massachusetts Institute of Technology decided to take up the challenge.

Led by MIT civil engineer Linda Seymour, an international team of researchers conducted a thorough analysis of ancient Roman concrete and made two stunning finds … the ingredients in the concrete differed from what we initially thought and the method by which the concrete was mixed played a key role.

Chunks of Lime

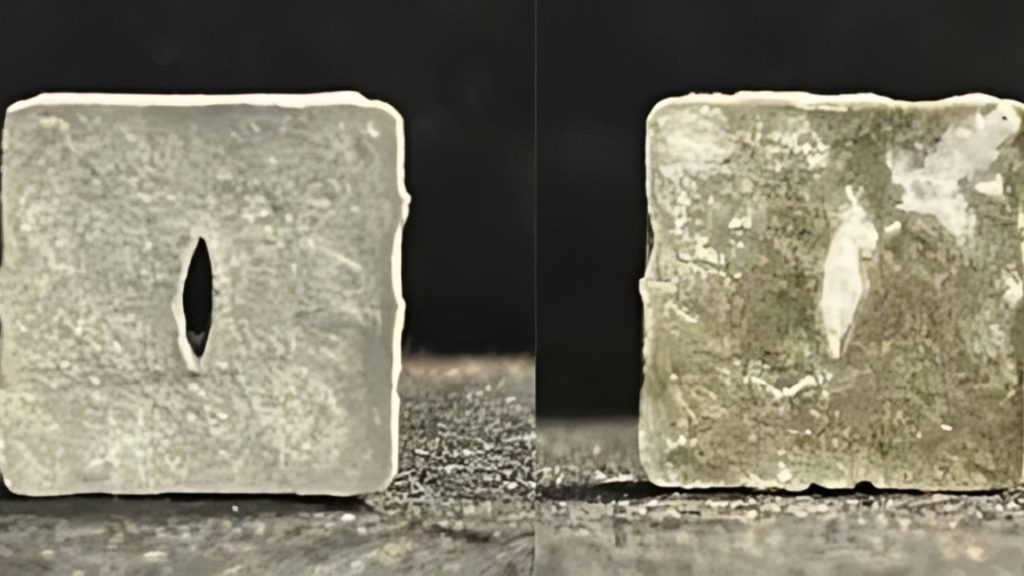

An inspection of ancient Roman concrete shows the presence of small chunks of white lime. In the past, it was assumed that these chunks resulted from poor mixing of the materials. But for MIT researcher Admir Masic, this didn’t make sense.

He explained, “The idea that the presence of these lime clasts was simply attributed to low quality control always bothered me. The Romans were meticulous about their building materials … they were not the type of people to tolerate shoddy workmanship.

Were the Lime Chunks the Key?

Masic observed, “If the Romans put so much effort into making an outstanding construction material, following all of the detailed recipes that had been optimized over the course of many centuries, why would they put so little effort into ensuring the production of a well-mixed final product?

Could the small chunks of lime have been intentional? Were they the key to the durability and longevity of Roman concrete? As Masic noted, “There has to be more to this story.”

Extensive Testing and Analysis

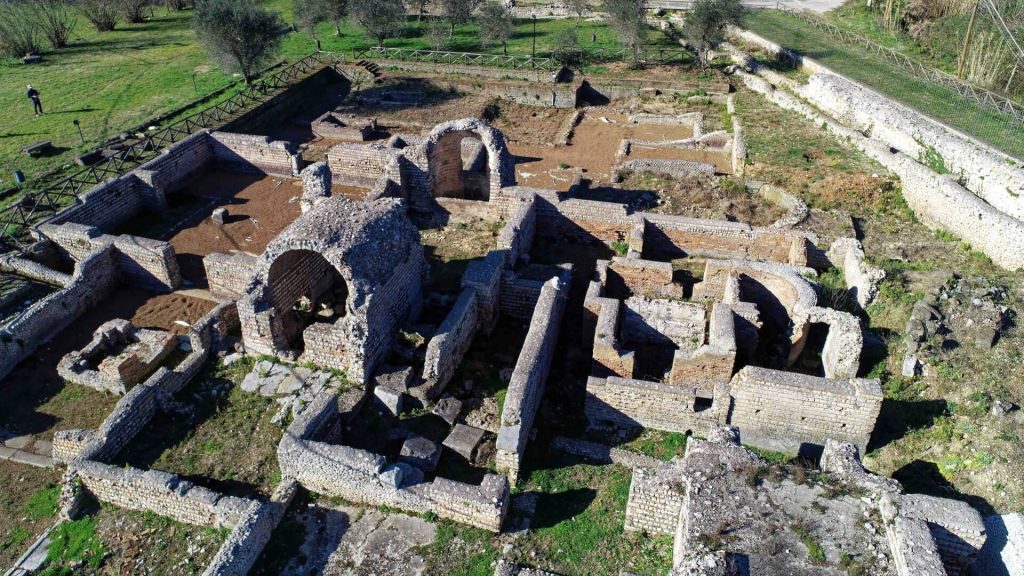

Seymour, Masic, and the rest of the team used concrete samples collected from the ancient Roman archaeological site in Privernum, Italy. They subjected these samples to an array of testing and analysis.

Using large-area scanning electron microscopy and energy-dispersive x-ray spectroscopy, the team uncovered more secrets about the samples. In addition, they used powder x-ray diffraction and confocal Raman imaging to more closely inspect the chunks of lime present in the concrete.

The Nature of the Lime

In the past, it was believed that Roman concrete was made with slaked lime. In making slaked lime, the limestone is burned or heated to raise its temperature. This created calcium oxide, better known as quicklime.

When quicklime is mixed with water, it produces calcium hydroxide, or slaked lime. Calcium hydroxide is not as caustic as calcium oxide. The prevailing theory was that the ancient Romans used slaked lime or calcium hydroxide when making their cement.

A New Theory Has Emerged

The MIT research team’s extensive analysis has resulted in a new theory. They now believe that the Romans mixed quicklime and slaked lime with pozzolana ash, and heated water all together at once, bringing the mixture to extremely high temperatures.

This process of making concrete has been called “hot mixing” by the MIT researchers. When the ingredients are combined using hot mixing, lime clasts are formed. But these chunks of lime, as we will see, are beneficial.

Hot Mixing Changes the Chemistry

As Masic explained, “The benefits of hot mixing are twofold.” The high temperatures change the chemistry of the materials and, more importantly, how they bond together. “When the overall concrete is heated to high temperatures, it allows chemistries that are not possible if you only used slaked lime, producing … compounds that would not otherwise form.”

In addition, as Masic noted, “This increased temperature significantly reduces curing and setting times since all the reactions are accelerated, allowing for much faster construction.”

The Self-Healing Lime Clasts

The researchers also determined that the inclusion of lime clasts give the Roman concrete the ability to “heal” itself. When cracks inevitably form in the concrete, they have a tendency to follow where the lime clasts, which have higher surface areas, are located.

Then, when water seeps into the cracks, it chemically reacts with the lime casts. The water becomes a calcium-rich sludge that, when hardened, becomes calcium carbonate. The calcium carbonate, in effect, becomes a caulk that fills and patches the crack.

Testing the Hot Mixing Method

Masic explained that the MIT researchers tested their findings by making their own concrete using the hot mixing technique, along with a control concrete without quicklime. They observed that cracks in the hot mixed concrete patched itself while the regular concrete did not.

You may soon be able to use Roman concrete on your own home improvement projects. The researchers are hoping to commercialize the concrete for industrial and personal use as an environmentally friendly and more durable concrete product.